Bespoke and modular lines allow large international brands and small, independent manufacturers to maximise product quality and elevate the perception of their brand

Sovereign Labelling Machines (Sovereign) is the leading UK-based manufacturer of bespoke labelling and sleeving machinery.

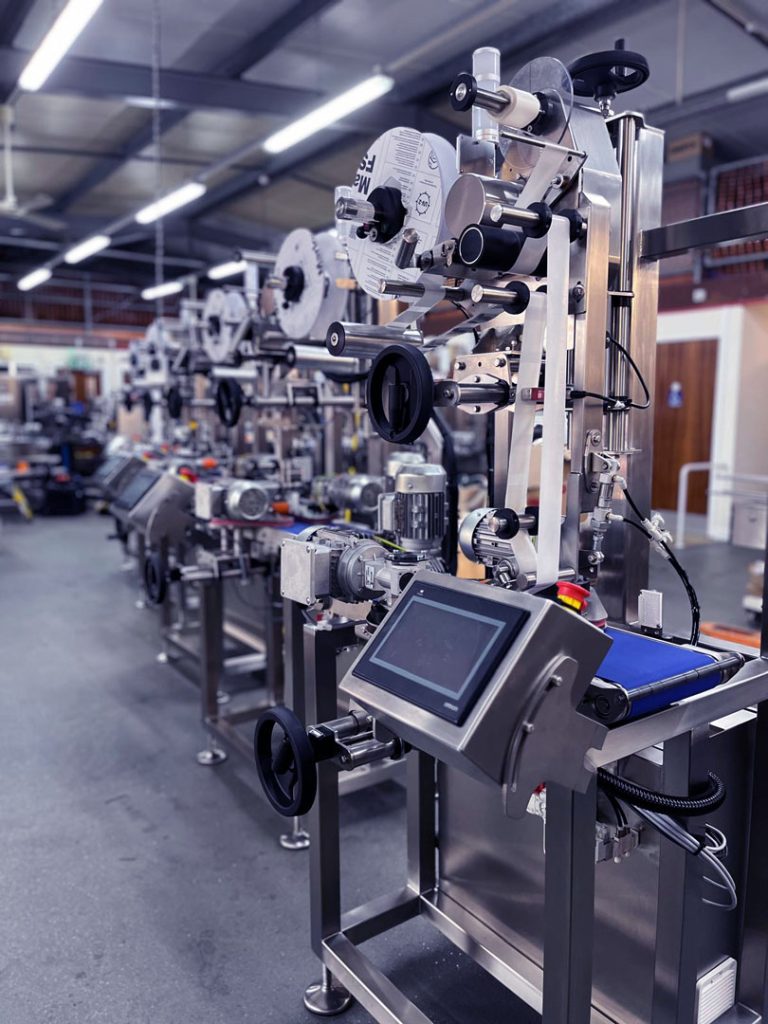

From its manufacturing site on the Essex coast, the company is synonymous with excellence in the design and construction of high-end machinery for accurate and efficient application of labels and sleeves to bottles, jars, cans, and a host of other containers.

Whether that is for: applying labels onto three sides of food packs (C-wrap); labelling milk bottles; precise placement of front and back labels on beverage bottles; multiple labels stuck to small cosmetic products; full body, tamper evident, and stretch sleeves; or even placing labels on undulating, sloped, curved, or spherical surfaces, the company’s systems are tailored to suit each client’s exact requirements.

This has resulted in machines being supplied to brands and co-packers working in a wide variety of demanding areas, from food and beverage, cosmetics and pharmaceuticals, to logistics and other professional applications.

Thomas Glendinning, Managing Director at Sovereign, said: “We have an exceptionally strong reputation in the UK and are cementing that with continued investment in our product development, infrastructure, and team.

“To support our future growth, we are expanding our reach into international markets and strengthening the working relationships we have with our OEM partners.”

Another development spurring on Sovereign’s growth is its position as a member of The ENE Group. The business was founded in 1993 and became part of The ENE Group in 2018, coinciding with its 25-year anniversary.

The ENE Group is renowned for the design and manufacture of custom processing line machinery, including conveyors and belts. This gives Sovereign direct access to essential components for the success of its lines.

The relationship makes Sovereign unique in the UK and grants it end-to-end control over the manufacture of bespoke, high-quality labelling and sleeving solutions.

Jordan Hynes, Sovereign’s Business Development Manager, explained: “We can proudly state that we manufacture all of the machine parts used to build our lines in the UK. That is the ultimate in quality control.

“Having that level of control ensures each component is manufactured to our own specifications, with exact tolerances that can’t be achieved when using off-the-shelf parts.

“It is this attention to detail that has given us such a strong reputation in the market and allows us to put equipment into the field that is delivering the highest quality output.”

In the steel

The power and purpose in this relationship is demonstrated at PPMA Total Show 2025, where on Stand G10, Sovereign presents a turnkey solution for bottle labelling.

This sees containers travel from an infeed rotary table onto a conveyor system which feeds directly into a Sovereign Monarch tri-roller/top labeller. A Sovereign Jubilee tamper evident sleever and portable heat tunnel then apply and form shrink sleeves to the neck and lid of the bottle, securing the lid in place and providing enhanced product security. Fully labelled and sleeved products are then presented to the outfeed rotary table for packing.

Sovereign also uses this system to showcase its capability to integrate complementary, third-party technologies and processes into its lines. These are treated with the same precision and attention to detail as if they had been manufactured by Sovereign.

At PPMA Total Show 2025, this includes a fully integrated thermal transfer printer for printing best-before dates onto the labels before they are applied. Once the labels have been successfully applied by the Sovereign Monarch labeller, an intelligent sensor looks for any missing labels and directs defective products to a reject chute.

“By linking all of the steps together and presenting them as a turnkey solution, we demonstrate our understanding of the market and the skill to meet the vast array of requirements across multiple industries,” Thomas comments.

Jordan continued: “The ability to do late-stage printing and customisation just before labelling is extremely important to today’s brands and co-packers. For example, with consumers actively looking to make more sustainable choices and minimise their environmental footprint, it is essential to be able to respond to heightened demand for smaller batches and evidence provenance. A consequence is demand for improved label inventory management, which our systems allow.

“This is almost impossible to manage if you are a small, independent brand who is still manually applying labels. That is where our industry-leading desktop labeller designed specifically for a wide range of round containers comes in.”

This system offers a low total cost of ownership (TCO) and has been designed for versatility. This makes it suitable for all types and size of business, regardless of their labelling and sleeving requirements.

Also on show on Stand G10 at PPMA Total Show 2025, this system can accommodate a wide range of products and label/sleeve sizes. Set-up and changeover is simple, making the system straightforward to use. A variable speed servo-driven applicator head and single point nip roller drive assembly ensure the same accuracy in label control and placement as high-volume labelling lines. In addition, a thermal inkjet printer can be integrated for printing codes and other key information.

“This is a killer system for the many thousands of artisan and craft brands operating in the UK today. They could be producing preserves to a family recipe passed down from generation to generation or making award-winning beers, ciders, and spirits. Either way, they need the same high-quality labels and labelling as the big brands to compete in a competitive market.

“Co-packers will also find a desktop labeller useful as a complement to their volume lines, as it allows them to more efficiently handle last minute requests and quick-turn work.”

Behind the steel

As important as the machines are the people behind the business.

Thomas has been with Sovereign for just over six years and has extensive experience in both FMCG-based and engineering businesses. Jordan joined Sovereign in August 2024 and brought robust knowledge of labelling to his role.

They have now been joined by John Walsh, who complements and completes Sovereign’s work to support and service customers throughout the UK. Having spent more than 25 years working in coding and labelling, he is ideally placed to grow Sovereign’s presence in the market.

With Jordan covering the south of England and Wales, John handling the north and Scotland, and Thomas responsible for all of Ireland (NI and ROI), the company is now closer than ever to its customers and prospects. Moreover, 50-plus years of collective experience means Thomas, Jordan, and John can advise, liaise, and support customers with all of their labelling and sleeving challenges.

“The combination of our years of experience and the cutting-edge machinery we offer, which is fully modular and built to order, puts Sovereign in an unrivalled position,” concludes Thomas.

“We are able to deliver the highest standards of quality and precision as well as the flexibility, speed, and reliability that today’s fast-moving supply chains demand.”

Contact Sovereign Labelling Machines:

+44(0)1206 304 182