From start to finish – and everywhere in between: REA UK and the future of FMCG traceability

In the fast-paced world of Fast-Moving Consumer Goods, things don’t just move quickly –they’re traceable, trackable, and regulated at every turn. Or at least, they should be. At REA UK, we’ve made it our business to ensure that FMCG producers don’t just keep up – they stay ahead.

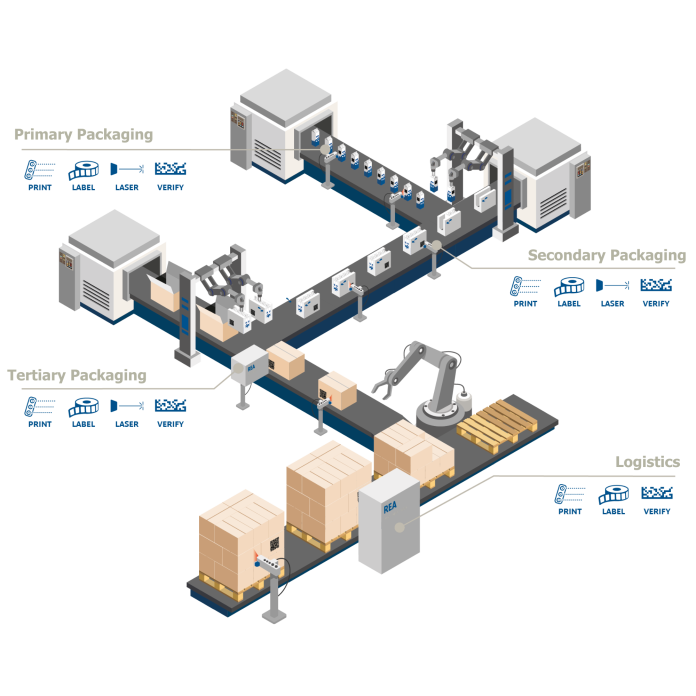

From the start of the production line, through to final packaging and dispatch, REA’s coding and marking systems are embedded at every critical stage. Whether it’s printing on primary packaging, applying variable data to cartons, labelling of pallets, or verifying the scan-ability of a 2D code before the product leaves the line, we’re there – quietly, precisely, and reliably.

As traceability evolves, so too must the technology that supports it. That’s where Ambition 2027 comes in – a GS1-led global initiative set to transform how we view on-pack data. In short? The humble barcode is getting a serious upgrade.

From barcodes to 2D codes – transparency reloaded

If you haven’t yet heard of Ambition 2027, here’s the headline: by 2027, the traditional EAN barcode will begin to phase out, replaced by 2D codes like QR and Data Matrix that carry significantly more information in the same space AND are more robust. It’s not just about better tech – it’s about transparency and trust.

For FMCG brands, this marks a turning point. 2D codes can carry batch numbers, expiry dates, country of origin, carbon footprint, recycling instructions — even digital product passports. And consumers are ready for it. They want more visibility into the products they buy, and with a single scan, 2D codes will tell the full story.

Our role: behind the scenes, at the centre of it all

While 2D codes might look simple, ensuring they’re correctly applied, formatted, and scannable across the entire supply chain is anything but. That’s where REA UK comes in.

We offer robust, integrated systems for inkjet, laser, and label-based marking — and crucially, we also provide inline code verification. Our technology ensures that every code is applied with precision and meets international readability standards, including ISO/IEC 15415 and GS1 Digital Link.

We make sure every code performs exactly as it should.

Partnerships that stick (just like our labels)

We don’t believe in one-size-fits-all. Every production environment is different, which is why we work closely with our customers to deploy marking and coding solutions that are tailored, scalable, and future-ready.

Whether you’re a global brand or a local challenger, navigating the future of traceability doesn’t have to be overwhelming. With REA, you’re never doing it alone.

Our message is simple: We’re with you from start to finish – and everywhere in between.

Visit REA UK at FACHPACK 2025, 23–25 September in Nürnberg –

where we’ll be showcasing how we turn codes into powerful tools for transparency, traceability, and trust (booth 1-233).

Website: www.reajet.co.uk

Tel: 01235 835 446

Email: info@reajet.co.uk